Denbergloss Low Reflection

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

Denbergloss Low Reflection www.denber-paints.co.il

Unique development – aviation polyurethane paint with special Microfiber carbon for coating airplanes and helicopters and other military land weapon and equipment for land and naval combat, for “stealth” effect, creating exceptionally low return of electro-magnetic waves, creating losses of light absorption Bar– Lambert law, prevents discovery by radar systems of radio frequency RF WAVES in HF(high frequency) 3 – 30 MHz in longitudinal waves in the field of 10-100 meters as Marine radar systems, coastal systems, to extremely high frequency (EHF-extreme high frequency), 30-300 GHz In longitudinal waves of 1 – 10 mm (MMW Millimeters waves). In developed radar systems as Apache/black hoke helicopters of the type AH-64D that can identify objects even in adverse weather conditions at high resolutions.

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

Top hard two components paint for monolithic coating creates a sharp change in the dialectic conductivity parameters of the substrate or diamagnetics of painted surface aircraft and combat helicopters, combat ships, logistic land vehicle and equipment and more… UV resistant, durable in harsh conditions including chemicals and abrasion resistant in contact of air, sand and sea water, winds and rainfall etc. Produced from pigments and fillers “swallow radar wave energy”, light waves, radio waves and electromagnetic communications.

Conservation of energy: r2 + t2 + a2 = 1 (“r” and “t” are the reflection coefficients, “a” is loss of energy, as you increase the energy loss due to ingesting and spread of such waves as resulting from un smooth surface, reflection coefficients are smaller and we get low reflection).

Denbergloss Low Reflection

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

Properties:

- Swallow all kinds of radio/radar/infra-red waves, electromagnetic waves, light waves. Creates effect “stealth” for air crafts, battleships, and logistical military equipment wants to hide from radar.

- Hard and rough finish for jets and combat helicopters, vessels and military logistics want to hide and avoid radar detection.

- Rigid and flexible, washable and very resistant to extreme heat and cold.

- Micronized roughness coating, provides exceptionally low reflectance.

- Excellent adhesion to infrastructure on suitable primers..

- Easily implemented.

- UV durable, chemicals durable, oils and fuel durable.

- Deep mate gloss in camouflage shades.

- Does not contain cadmium, lead, chromates, and titanium.

- Suitable for camouflage and evading from radar monostatic, pseudo-monostatic, multi static.

- Suitable for avoiding exposure of big radar stations, local radars and control towers and ships.

- and Suitable for “stealth” effect from airborne radar, fighter planes and passenger jets.

- Suitable for avoiding very high percentages of electronic scan array radar with a managed array antenna managed phase and installed on the F22 , F35 jets AESA radar

Applications:

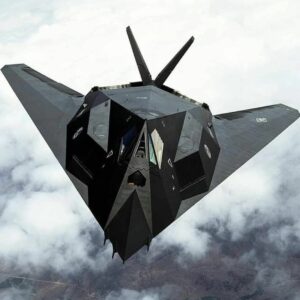

- Stealth fighter jets as F 117, F-22, F-35 and all fighter air crafts.

- Paint all types of battle choppers.

- Painting all types of military vessels.

- Painting military land logistical vehicles and field equipment

- and Painting missals.

- Painting ground facilities want to vanish from radar.

Denbergloss Low Reflection

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

Technical data:

- Part A – can be mixed manually easily, after 5 minutes you will get a smooth and uniform solution.

- Part B – to be transparent and clear.

- Storage stability – 24 hours 57 0C with no separation or spoiling,

- Theoretical coverage – 1 liter to 5-10 sqm.

- Layer thickness recommended – 60-120 microns dry.

- Recommended no. of layers : 2-3

- Flexibility – 1 mm ( sheen )

- Density – 1.1 1.4 gm\cm 3

- Viscosity average A + B – 1-6 Pa. sec

- Hardness – >10 Dg (Erichsen)

- Erosion – 120 microns-2800 cycles (Gardner) ASTM

- Ratio A:B – 2: 1

- Color tolerance stability time – 6 hours undiluted package (increase in viscosity of no more than 6 seconds from authentic)

- Grinding – > 5 matte Hegman

- Gloss in 600 – matte < % 5

- Hue changes allowed – Delta E – <1.0

- Pot life – once mixed B + A – 4 hours.

- Distilled water durability – without loss of adhesion or corrosion after 24 hours .

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

- Carbons durability – without losing adhesion 1h after out of the liquid.

- Oil durability (oil 1250) – 24 hours in O C 121 without losing adhesion 4 hours after check-out of the liquid.

- Resistant hydraulic oil in 24 hours O C 66 – without losing adhesion 4 hours after check-out of the liquid

- Jet fuel resistance 7 days in room temp. without loss of adhesion – 4 hours after check-out of the liquid

- Heat resistance – O C 121 for 60 minutes. no shade changes Delta E = 1.

- Humidity cabinet test – 30 days 100% humidity in O C 49 without losing adhesion or damage after check-out of the liquid

- Salt spray – 3000 hr. without the appearance of corrosion.

- Thermal shock – without lose of adhesion.

- % solid – 66%,

- Lacquer base test durability in accelerated conditions based on this product: 1,000 hours in Q-Panel with lamp UVA RADIATION-340 cycles of 8 hours of light at 600C and 4 hours of 500C, lacquer passed the test successfully with minimal shade changes and without harm to mechanical features.

- This test has been edited in the ministry of defense – materials laboratories and appendix to this specification.

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

- Suitability to frequency range:

| Frequency range | Frequency width | Wavelength | Description |

| HF | 3-30 MHz | 10-100 meter | High frequency for shore radar |

| VHF | 50-330 MHz | 0.9-6 meter | Very high frequency for long range bypass obstacles |

| UHF | 300-1000 MHz | 0.3-1 meter | Ultra high frequency for longer range bypass obstacles to detect ballistic missiles |

| L | 1-2 GHz | 15-30 cm | Long – long range air control for long ranges |

| S | 2-4 GHz | 7.5-15 cm | Short – short ranges aviation/marine

|

| C | 4-8 GHz | 3.75-7.5 cm | Satellites |

| X | 8-12 GHz | 2.5-3.75 cm | Radar missiles focusing, land radar, air craft fields |

| Ku | 12-18 GHz | 1.67-2.5 cm | Satellites high |

| K | 18-27 GHz | 1.11-1.67 cm | Meteorology |

| Ka | 27-40 GHz | 0.75-1.11 cm | Short range |

| mm | 30-300 GHz | 1-10 mm | Milimetric waves

|

| EHF | Extreme high frequency (installed on apache helicopters AH-64D) |

- Absorption tests (on pyramidal radiation absorbent RAM):

5 MHz – 96-100%

10 MHz – 96-100%

- Absorption tests (on sandwich form radiation absorbent RAM):

5 MHz – 98-100%

10 MHz – 99-100%

Denbergloss Low Reflection

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

Contains:

- Suitable polyol

- Fe carbonyl

- MWNTs – multiwall nano carbon tubes

- Fillers nano-tech, durable pigments.

- Special flex materials.

- Solvents, additives.

- Part b – aliphatic isocyanates UV durable, a special blend

Colors:

- 37038 matte black, matte blue 35109, Matt Brown, 36463 30219 gray matte-FED. St., 595

- All shades of 595- FED- st . aviation and marine.

Gloss:

- Deep matte.

Touch dry:

- 30-60 minutes, between layers: 6 hr. dry hard: 8 hr., final: 24 hours.

Application methods:

- spray

Dilution:

- For spraying – 15-35% thinner D- 11 pressure 3- 4 atm.

Surface Preparation:

- Clean from dust, fat, dirt and lose paint.

- Sand gently and wipe out with Degreezer M.

Denbergloss Low Reflection

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

Primary paint:

- Epoxyden primer aviation “MIL-C-PRF-23377G strontium chromate for aluminum.

- Epoxydem primer anti rust rust converter for steel ships and equipment and logistical ground vehicles and combat weapons.

- Polyflex primer for polyethylene for complexes materials

Package:

- 3.4 +1.6 = 5 liters. 10+5=15 liters

Storage:

- In cool, shaded room.

- Keep lids tightly closed/

Shelf life:

- 12 months in the original packaging.

Cleaning tools:

- Thinner D- 11 at the end of painting.

Quality control:

- In factory laboratories according to specifications.

- COA and COC certificate.

- ISO 9001-2015

Denbergloss Low Reflection

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

Safety precautions:

- Inedible, keep away from the reach of children.

- Flammable – keep distant from heated areas, fires, flames, and sparks, Prohibit smoking in working area.

- While applying, good air ventilation is important. In case there is not enough air, use ventilation according to the ventilation table.

- Wear protective glasses, gloves and suits.

- Avoid direct contact of the paint and/or thinner with the eyes and skin. In case of contact, immediately wash thoroughly with water.

- In case of an injury immediately get doctors assistance.

- Read the safety instructions on the labels.

- See M.S.D.S

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

Warnings:

- Don’t mix the product with materials which were not recommended by us.

- Don’t apply if the temperature is under +7°C.

- and Don’t apply if humidity is over 80%

- When applying with Airless, do not aim it at anybody a direct hit could be fatal at pressures over 150 atm.

- Read thoroughly the technical data of the product listed in this section; confirm that everything is understood completely, for clarification contacts our tech. department.

- All information that is listed in this content is a recommendation merely and cannot be applied in the court of law.

- The costumer must test & check that this product is compatible with his equipment and needs.

- The information listed in this section is according to the laboratory conditions (temperature, humidity etc.) which the products were tested.

- and The recommendations listed do not hold any responsibility for this product.

- Theoretical and actual coverage area are different concepts, the actual coverage is affected by the required thickness of the layers, required number of layers, painting conditions including the amount of paint which spread in the air before touching the surface.

- The information listed in this section is based on experience and accumulating data, Denber inc., has the right to change the information listed at any time.

- Paints that have been in stagnation or exposed to air more than needed could have their qualities changed.

Denbergloss Low Reflection

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

Clarifications:

- Storage room temperature 15°C to 25°C .

- Over Spray: An effect which occurs in the spraying of paints application. A type of “dust” is created by dry gases of the air, which causing the paint particles to fall dry on the surface (hereafter the “effect”). The impact of this “effect” becomes stronger due to over pressure and heat, (most sprayers have a lever to control the pressure) To avoid the negative impact 0f the “effect”, the pressure of the spraying should be lowered to the necessary minimum!. Another possibility is to increase the amount of the thinner in the mixture which would cause the paint particles to fall wetter on the surface.

An additional recommended possibility, to avoid this “effect”, is to add a retarder to the mixture which increases the duration period of the painting application , avoiding the paint to dry up, and enabling it to reach the surface wetter, Thus a better painted smooth layer is formed.

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

- Pot Life: The working time which is possible to paint a mixture of two components, A+B (or more) without spoiling the qualities of the paint or disqualifying the paint as “out of use”.

- Spray: It is possible to spray with a sprayer that has a container holding the paint that sprays it with air pressure.

- Airless: a device with a piston which compresses the air for spraying paints. The pressure might be high (over 100atm.) Don’t aim it at anyone

- Surface preparations: the level of cleanness is determined by international standards. Surface preparations, including cleansing sand blasting, is important & critical factor in achieving an optimal result for painting adhesion on a certain surface. These standards are equally compared to the standards of the Swiss SA, the German-Din the U.S SSPC SP For each standard in any level there are indicators, for sale, in order to make visual comparison between the cleansing of the surface and the indicator.

Denbergloss Low Reflection

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

Quality inspection:

- Prior to the painting on large surfaces it is important to test the product on a small area, to be sure that the paint is compatible with the level of satisfactory.

- Laboratory testing was made according to the standards institution specifications.

- This “Data sheet” given as noncommittal information, the product above recommended for professional painting specialists. This information is not a substitute to personal guidance.

- You must read the MSDS safety instructions before you start working with the product.

Environment conditions for application:

- The paint must be mixed until homogeneous and ready for application. The temperature critical limits in the painting booth are 16OC-38OC, recommended working temp.: 20OC-32OC, the humidity critical limits are 20%-80%, recommended working humidity: 20%-65%

Denbergloss Low Reflection

Rough textured paint, swallow radar beams and reduces reflection of infrared rays

- For more information about Denber Paints and Denber Projects, please contact us by phone and/or to the company’s websites:

- company profile English also

- For more details please refer to the Denber website also

- For our Facebook page click here also

- To the Facebook page of the CEO of Denber also

- For more projects click here also

- To the article: Sealer for stone and concrete and marble also

- To the article: Thermal insulation in nanotechnology also

- article: Thermal insulation Thermosil 200 energy saving in green construction also

- Related article: Thermal insulation, floor coating also

- To the article: Thermal insulation in nanotechnology company Denber also

- Fire resistance of houses, hardwood and parquet floors, decks also

- Swelling paints for steel protection against fire – Fire retardant paint also

- Epoxy floor coating in casting and painting also

- Crystal epoxy resin for tables also

- To the article Sealing also

- The complete article on the sealing materials for roofs and walls also

- Sealing the floor of the balcony, terrace from rain also

- Mold, how to remove mold correctly and how to fight mold also

- “Sick” buildings – Antibacterial paints Bacterinoll/ Tutgum Bacterinol also

- Paint for aircraft Denbergloss Jets also

- Asphaltflex execution specification – Denber Paints also

- Denbergloss grainy car paint also

- Denbergloss Clear also

- Varnish for wood. How to choose the right varnish for wood also

- Crystal epoxy for tables from Denber also

- Paint for swimming pools, epoxy Epoxyden Dengal, performance specification also

- Color specification of quadrant helmets also

- For a free consultation, call Denber – Dr. Blen Evgenia – 050-3551549 / 050-3551551 also

- Need advice? Contact us by email: Denber@bezeqint.net or contact us at 08-9960794

English

English עברית

עברית Русский

Русский