AQUA FLEX SUN REFLECT

TRANSFERING LIGHT AND REJECTING HEAT

AQUA FLEX SUN REFLECT. www.denber-paints.co.il

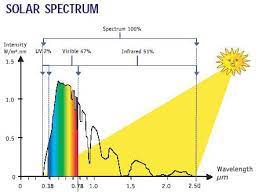

Translucent greenish water base polyurethane paint heat reflecting, for painting on external exposed to the sun glass, surfaces and elements. Repellent the solar heat radiation up to 85% and prevents warming, also filters and pass the sunlight beams.

AQUA FLEX SUN REFLECT

TRANSFERING LIGHT AND REJECTING HEAT

AQUA – FLEX SUN REFLECT Reflects the sunlight’s invisible heat radiation, while allowing the majority of the visible light to pass.

Protects sensitive facilities, devices and buildings from overheating from the warming rays of the sun and thus by reflecting them, one component paint , very easy to use, for external uses.

This paint also produced as “Denbergloss sun reflect” – a two component polyurethane for high durability demands.

Properties:

- Returns the most of the Sun’s heating rays and prevents overheating from the painted surface.

- Prevents overheating of the buildings and facilities that are with people and equipment.

- Green product-water base, one component easy to apply.

- Economic , for coating in thin layer

- Contributes to a considerable saving in energy for cooling

Applications:

- For painting external stone/wooden walls, Windows and roofs, of residential, facilities and industry.

- Paint the outside metal walls and roofs and tin metal structures heating in the Sun.

- Paint the outside of the passengers vehicles exposed in hot countries to the heat of the sun especially in desert conditions,

- External painting of containers/wagons with equipment.

- External painting of closed military vehicles

- Agriculture equipment etc. work under sun all day, on motor area and driver cabin.

AQUA FLEX SUN REFLECT

TRANSFERING LIGHT AND REJECTING HEAT

Technical data:

- Effective coverage – 1 liter to 8 sqm.

- Flexibility – 1 mm (sheen)

- Density – 1.3-1.35 gm\cm3

- Viscosity – 1000-3000 Pa s (Brookfield)

- Hardness — >3 Dg (Erichsen)

- Erosion – 120 microns film – 850 cycles (BYK Gardner) ASTM

- Layer thickness recommended – 125-150 microns wet.

- The number of layers is recommended – 1-2

- Heat reflectance – average 80-85% refund, on white color metal sheets and

white “Polyflex roof” coating surface (SRI ASTM E 1980 = Reflectance ASTM E903 : Surface Remittances ASTM 408 E)

- Heat refund – 90-100% heat refund on average on white TPO sheets, and surfaces coated with aluminium foil.

Contains:

- Polyurethane high quality emulsion durable in extreme weather conditions.

- Fillers, pigments.

- Special flexible materials.

- Additives.

Colors:

- Translucent clear/ greenish.

AQUA FLEX SUN REFLECT

TRANSFERING LIGHT AND REJECTING HEAT

Gloss:

- Silky

Touch-dry time:

- 60 min. (Due to the quick drying time from over spray avoid spraying “dust”) if creates “dust” while spraying, add retarder and lower the air pressure.

Drying between layers:

- 6-8 hours. Final: 24 hours.

Application methods:

- Brush, roller, spraying

Dilution:

- Water

- Brushing/roller – 10-20%

- Spraying – 30% for first layer, second layer – 5%.

Surface preparation:

- A thorough cleaning from dust, dirt and loose paint.

- Sand grains to remove and clean with air pressure.

- Wash glass windows with acetone before painting.

AQUA FLEX SUN REFLECT

TRANSFERING LIGHT AND REJECTING HEAT

Primer:

- On new wall – sand lightly to remove the grains, and coat with “Denbertex primer” 1-2 layers to get white uniform surface.

- On Roofs – white Aqua Flex layer on tar/asphalt and/or bitumen sheets to get white uniform surface.

- On old paint – lightly sand, clean the dust, grease and loose paint, coat with “denbertex primer” to get white uniform surface.

- Old roofs – high pressure washing, waiting for drying and a layer of white aqua flex.

- On the metal roof or walls – Tutgum universal white.

- On steel containers with people or equipment, Armored vehicles, vehicle transporters and etc. – Epoxyden anticorrosive rust converter primer.

Packaging:

- 5-liter, 18 liter.

Storage:

- In cool and shaded room with appropriate ventilations.

- Keep lids seal.

Shelf life:

- 12 months in original package.

Tools cleaning:

- Water and soap after painting.

AQUA FLEX SUN REFLECT

TRANSFERING LIGHT AND REJECTING HEAT

Quality control:

- In factory laboratories according to specifications.

- COA and COC certificate.

- ISO 9001-2015

Safety precautions:

- Inedible, keep away from the reach of children.

- While applying, good air ventilation is important. In case there is not enough air, use ventilation according to the ventilation table.

- Wear protective glasses, gloves and suits.

- Avoid direct contact of the paint and/or thinner with the eyes and skin. In case of contact, immediately wash thoroughly with water.

- In case of an injury immediately get doctors assistance.

- Read the safety instructions on the labels.

- See M.S.D.S

Quality inspection:

- Prior to the painting on large surfaces it is important to test the product on a small area, to be sure that the paint is compatible with the level of satisfactory.

- Laboratory testing was made according to the standards institution specifications.

- This “Data sheet” given as noncommittal information, the product above recommended for professional painting specialists. This information is not a substitute to personal guidance.

- You must read the MSDS safety instructions before you start working with the product.

AQUA FLEX SUN REFLECT

TRANSFERING LIGHT AND REJECTING HEAT

TRANSFERING LIGHT AND REJECTING HEAT

- For more information about Denber Paints and Denber Projects, please contact us by phone and/or to the company’s websites:

- company profile English also

- For more details please refer to the Denber website also

- For our Facebook page click here also

- To the Facebook page of the CEO of Denber also

- For more projects click here also

- To the article: Sealer for stone and concrete and marble also

- To the article: Thermal insulation in nanotechnology also

- article: Thermal insulation Thermosil 200 energy saving in green construction also

- Related article: Thermal insulation, floor coating also

- To the article: Thermal insulation in nanotechnology company Denber also

- Fire resistance of houses, hardwood and parquet floors, decks also

- Swelling paints for steel protection against fire – Fire retardant paint also

- Epoxy floor coating in casting and painting also

- Crystal epoxy resin for tables also

- To the article Sealing also

- The complete article on the sealing materials for roofs and walls also

- Sealing the floor of the balcony, terrace from rain also

- Mold, how to remove mold correctly and how to fight mold also

- “Sick” buildings – Antibacterial paints Bacterinoll/ Tutgum Bacterinol also

- Paint for aircraft Denbergloss Jets also

- Asphaltflex execution specification – Denber Paints also

- Denbergloss grainy car paint also

- Denbergloss Clear also

- Varnish for wood. How to choose the right varnish for wood also

- Crystal epoxy for tables from Denber also

- Paint for swimming pools, epoxy Epoxyden Dengal, performance specification also

- Color specification of quadrant helmets also

- For a free consultation, call Denber – Dr. Blen Evgenia – 050-3551549 / 050-3551551 also

- Need advice? Contact us by email: Denber@bezeqint.net or contact us at 08-9960794

English

English עברית

עברית Русский

Русский