Epoxyden Рost fluorescent Glow at darkness

Glow at night epoxy paint for floors

Epoxyden Рost fluorescent Glow at darkness. www.denber-paints.co.il

Epoxyden Рost fluorescent Glow at darkness. www.denber-paints.co.il

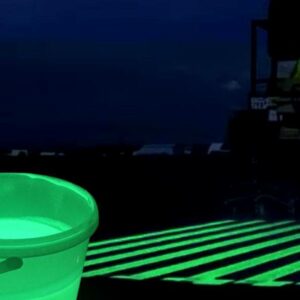

Epoxy glow at night coat bi component, high build, very strong heavy duty, erosion and friction durable, as thick layer marks on floor to glow at darkness ang guide the way when the lights are off. Very popular in industrial flooring in factories and warehouses, public facilities like hospitals, dining rooms, etc. 100% solids, self-leveling, special for coating by pouring monolithicthick lineson floors. Durable in harsh conditions including abrasive and chemicals resistance.

Epoxyden Рost fluorescent Glow at darkness

Glow at night epoxy paint for floors

Properties:

- Glow at darkness and in emergency shows the way out.

- Can be poured in one thick layer without thickness limiting.

- 100% solids, no solvents evaporation.

- Smooth and high hardness finishing, scratch durable.

- Easy to wash and reject dirt and dust.

- Durable in washing floors chemicals without solvents.

- Very good adhesion to any hard infrastructure including cement and steel alloy with appropriate primer coat.

- Easy to apply as it is self-leveling.

- Durable in agricultural chemicals, industry chemicals, oils, fuels.

- Resistance to heat and cold.

- Durable in high humidity ant salty environment, in acids and alkaline.

- Durable in standing water with industrial waste for long periods of time.

- Does not contain cadmium, lead, chromates.

Applications:

- For painting lines and signs on floors to show the way is case light are off.

- Public places like cinema and theater halls, busses, trains, airplanes, etc. all needed warning and guide signs have to be seen in darkness or in emergency situation with no light.

- Signs and traffic directions at darkness.

- Lines and direction gaudiness to exits in case of light shut down.

- Headers and emergency exits.

Epoxyden Рost fluorescent Glow at darkness

Glow at night epoxy paint for floors

Technical data:

- Part A– can be mixed easily, and in 5 minutes you’ll receive a smooth and uniform solution.

- Part B – transparent and clear.

- Storage durability – 24 hours at 570 C with no sagging or corruption.

- Coverage – 1 liter to 1 sqm. in 1 mm. 3 liter to 1 sqm in 3 mm thickness. 1 liter to 2 sqm. for 500-micron thickness.

- Recommended minimum thickness of layer-300micron.

- Density – 1.2-1.4 gm\cm3

- % Solids – 100%.

- Ratio – 2:1 (base-2, hardener-1)

- Flash point part A – 255O part B – 166OC

- Hardness – >10 Dg (Erichsen)

- Elasticity – 4 mm (sheen)

- Bending strength – 30 N/mm2

- Viscosity average A + B – 12,000 cPs (Brookfield)

- Erosion – 120 microns – 4500 cycles (Gardner) ASTM

- Impact strength – 1.8 Dg/mm2

- Adhesion to concrete – higher than concrete strength.

- Adhesion to Epoxyden floor primer – 245 kg/cm2

- Elasticity in dragging – 10% N/mm2 (DIN 63457)

Glow at night epoxy paint for floors

- Dragging resistance – 8 N/mm2 (DIN 53455)

- Electric isolation for clear coat – 1.5×1014 ohm/cm3

- Pot life = working time from mixing A + B – < 20 minutes.

- Distilled water resistance for 24 hr. – without losing adhesion or corrosion 1 hr. after taking out of water.

- Carbon resistance – no loss of adhesion durability 1 after taking out of the solvent.

- Resistance to oil 1250 24 hours in 121oC – no loss of adhesion 4 hours after taking out of the oil.

- Hydraulic oil resistance 24 in 66oC – without losing adhesion 4 hours after taking out of the oil.

- Aviation Fuel resistance – 7 days in room temp. – without losing adhesion 4 hours after taking out of the fuel

- Heat resistance 121O C during 60 minutes – NO shade changes to Delta E = 1.

- Humidity cabinet – 30 days in 100% humidity in 49oC – no loss of adhesion or damage to the film after 1 hr. out of cabinet.

- Salt spray durability – 2000 hours with no corrosion occurs.

- Thermal shock – without adhesion loses.

Epoxyden Рost fluorescent Glow at darkness

Glow at night epoxy paint for floors

Contains:

- Epoxy resins and hardeners.

- Fillers, durable pigments.

- Special flexibility materials.

- Glow at night fillers.

Colors:

- yellow-greenish

Gloss:

- Glossy

Touch dry time:

- < 4 hours

Drying between layers and final:

- 16-24 hours, final: 24 hours, hard to use: 7 days

Application methods:

- Pouring and leveling with tooth spatula or roller, for taking of the air with thorns roller.

Ventilation:

- No solvent evaporation, 100% solids. Minimum ventilation needed.

Drying time 500 mic. according temperature:

- 7OC – first dry – 96 hours, final dry – 15 days

- 10OC – first dry – 48 hours, final dry – 10 days

- 15OC – first dry – 30 hours, final dry – 7 days

- 20OC – first dry – 24 hours, final dry – 3 days

- 30OC – first dry – 18 hours, final dry – 2 days

- 40OC – first dry – 12 hours, final dry – 1 day

Epoxyden Рost fluorescent Glow at darkness

Glow at night epoxy paint for floors

Dilution:

- Without dilution.

Surface preparation:

- Preparing concrete floors: planetary polishing with diamond stones in vacuum or shot blast machine.

- Perfect cleaning from dust, dirt or grease or loose paint with degreaser M

- Primer Epoxyden 450 for damp floors or Epoxyden floor primer – standard primer. See recommended primer for fire protection system –like Denber Epoxyden primer brominated.

- Fill holes with grout epoxy.

- Open the concrete cracks and stitches and fill with elastomeric 225A.

- With Diamond disk make thresholds (mechanical anchor) width of 1 cm and depth of 5 mm, in steel connection with concrete – this will be about 1 cm slot from the steel.

- Preparing metal surfaces: mechanical cleaning with brushes made of steel or clean with sand blast to get white metal SA 2.5. Chemical cleaning: removing rust and chemical burning with Denber rust remover 3000 and grease removing with Degreaser M

Primer:

- Epoxyden floor white primer.

Packaging:

- 3.4+1.6= 5 liter

- 10+5 = 15 liter

Epoxyden Рost fluorescent Glow at darkness

Glow at night epoxy paint for floors

Storage:

- In a cool shaded place in room temp. with proper ventilation.

- Keep lids tightly closed.

Shelf life:

- 24 months in original package.

Tools cleaning:

- Thinner 4/100-D at the end of painting.

Quality control:

- In factory laboratories according to specifications.

- COA and COC certificate.

- ISO 9001-2015

Safety precautions:

- Inedible, keep away from the reach of children.

- Flammable – keep distant from heated areas, fires, flames, and sparks, prohibit smoking in working area.

- While applying, good air ventilation is important. In case there is not enough air, use ventilation according to the ventilation table.

- Wear protective glasses, gloves and suits.

- Avoid direct contact of the paint and/or thinner with the eyes and skin. In case of contact, immediately wash thoroughly with water.

- In case of an injury immediately get doctors assistance.

- Read the safety instructions on the labels.

- See M.S.D.S

Epoxyden Рost fluorescent Glow at darkness

Glow at night epoxy paint for floors

- For more information about Denber Paints and Denber Projects, please contact us by phone and/or to the company’s websites:

- company profile English also

- For more details please refer to the Denber website also

- For our Facebook page click here also

- To the Facebook page of the CEO of Denber also

- For more projects click here also

- To the article: Sealer for stone and concrete and marble also

- To the article: Thermal insulation in nanotechnology also

- article: Thermal insulation Thermosil 200 energy saving in green construction also

- Related article: Thermal insulation, floor coating also

- To the article: Thermal insulation in nanotechnology company Denber also

- Fire resistance of houses, hardwood and parquet floors, decks also

- Swelling paints for steel protection against fire – Fire retardant paint also

- Epoxy floor coating in casting and painting also

- Crystal epoxy resin for tables also

- To the article Sealing also

- The complete article on the sealing materials for roofs and walls also

- Sealing the floor of the balcony, terrace from rain also

- Mold, how to remove mold correctly and how to fight mold also

- “Sick” buildings – Antibacterial paints Bacterinoll/ Tutgum Bacterinol also

- Paint for aircraft Denbergloss Jets also

- Asphaltflex execution specification – Denber Paints also

- Denbergloss grainy car paint also

- Denbergloss Clear also

- Varnish for wood. How to choose the right varnish for wood also

- Crystal epoxy for tables from Denber also

- Paint for swimming pools, epoxy Epoxyden Dengal, performance specification also

- Color specification of quadrant helmets also

- For a free consultation, call Denber – Dr. Blen Evgenia – 050-3551549 / 050-3551551 also

- Need advice? Contact us by email: Denber@bezeqint.net or contact us at 08-9960794

English

English עברית

עברית Русский

Русский