Epoxyden floor antislip

Epoxy Floor 100% Multi-Thickness Rough Anti-Slip

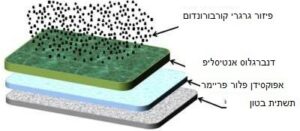

For coating floors by pouring with carborundum/quartz

Contain: 4 pages. 5 liter– 685315, 18-685314 Updated on October 12, 2018

Multi-thickness epoxy coating, in shades, extremely strong and thick, abrasion resistant, hard anti-slip coating for wet and/or oily floors in industrial production halls, kitchens and wet rooms, for wear resistance and chemicals in low concentrations and detergents. Used as a coating as a rough, 100% solid hard top, especially for coating monolithic floors in the cast for a uniform anti-slip surface.

Epoxyden floor anti slip www.denber-paints.co.il

EPOXY FLOOR 100% ANTISLIP – SOLVENTLESS EPOXY FLOOR COATING FOR ANTISLIP COATING OF INDUSTRIAL FLOORS BY POURING WITH SILICON CARBIDE.

Epoxyden floor antislip

Epoxy Floor 100% Multi-Thickness Rough Anti-Slip

Features:

- Folds by itself (SELF LEVELING) and forms a uniform granulated surface.

- Prevents slipping on both water and oil and allows safe walking without smoothness.

- Rough hard finish to concrete and steel floors.

- Multi-thickness, high hardness, abrasion resistant, suitable for the movement of forklifts and lift carts and carrying.

- Excellent adhesion capacity to Epoxyden floor primer.

- Easy to apply in the self-leveling with carborundum/quartz spread on top.

- Resistant to various chemicals, oils and fuels, in solvents, resistant to acids and bases at low concentrations – see Resistance table.

- Resistance to heat and cold. Resistant to unusual humidity conditions in fresh, distilled, salty water.

- Contains no cadmium, lead, chromates.

Uses:

- Coating floors and work surfaces on wet factory floors, damp rooms, work and maintenance rooms with oil, food kitchens with oil and water etc.

- Coating concrete floors and anti-slip steel.

- For Coating floors in washing rooms, dairies and slaughterhouses, pharmaceutical industry, meat and food factories, etc.

- Coating garage floors and car lubricant stations.

Epoxyden floor antislip

Epoxy Floor 100% Multi-Thickness Rough Anti-Slip

Technical data:

- Part A – It is easy to mix manually and after 5 minutes you will receive a uniform and smooth solution.

- Part 2 – will be transparent and clear.

- And Part C – Black Carborundum/Quartz.

- Storage durability – 24 hours in 570 separations and spoilage,

- Cover – 1 liter to 1 square meter in a layer of 1 mm.

- Maximum layer thickness is recommended – unlimited.

- Flexibility – 4 mm (sheen))

- Density – 1.2-1.4 gm\cm3

- Average viscosity A+B– 12,000 cPs (Brookfield)

- Subordination strength – 30 Newtons/square meters,

- Impact strength – 1.8 joules/sqm.

Epoxy Floor 100% Multi-Thickness Rough Anti-Slip

- Rigidity >10 Dg (Ericsson)

- Grinding – 120 microns – 4500 cycles (Gardner) ASTM

- Base ratio in gray /variety – 2.0:1 by volume, transparent – 2:1 by weight.

- Pot Life = working time from the moment of mixing B+A to 5-liter packaging – 20-30 minutes.

- Resistant to distilled water for 24 hours – without loss of adhesion or corrosion an hour after removal from the liquid.

- Carbon resistance – without loss of adhesion one hour after extraction from the liquid.

- Oil resistance 1250 24 hours in OC121 – without adhesion loss 4 hours after removal from the liquid.

- Resistance in hydraulic oil 24 hours in OC66 – no adhesion loss 4 hours after removal from the liquid.

- Jet fuel resistance – 7 days in room temperature – without loss of adhesion 4 hours after removal from the liquid.

- Heat resistance –OC121 for 60 minutes. No tonal changes until Delta E=1.

- Humidor – 30 days in humidity 100% temp. oC49 without loss of adhesion or damage to the film an hour after removal from the liquid.

- Salt spray cell – 3000 hours without the appearance of corrosion.

- Thermal shock – no adhesion losses.

- Solid % – 100%.

- Adhesion to steel – 210 kg / sqcm, adhesion to concrete – is more reinforced and tearing the concrete.

Epoxyden floor antislip

Epoxy Floor 100% Multi-Thickness Rough Anti-Slip

Contains:

- Proper epoxy resin.

- Fillers, resistant pigments.

- Flexibility additives.

- Additives.

- In part 2 – The hardener.

- In Part C – Carborundum/Quartz.

Hue:

- Transparent, gray and red standard and all RAL shades ,

GLOSS:

- Shiny, silky.

Drying to touch:

- 4 > hours in summer.

Hard drying:

- 24 hours, final hardness – 7 days.

- Between layers 16-24 hours.

Application methods:

- Floor – casting and leveling with a dental bar and air extraction with thorn roller. You can pour in one layer any thickness you want. It is recommended to pour at least 1 mm thick for load resistance and erosion of carts and pedestrians, forklifts 2.5 tons should be coated 3 mm thick.

- At the end of the pour, spread part 3 the carborundum aggregates. It should be spread uniformly and with required density.

- You can leave this way or pass over with the material with a thin layer roller to coat the bumps of the carborundum for a gentler, more decorative roughness. But the skating coefficient will increase accordingly.

Epoxyden floor antislip

Epoxy Floor 100% Multi-Thickness Rough Anti-Slip

Thinning:

- Floor – no dilution in the casting and leveling.

Preparing space:

- Thorough cleaning dust, fat, dirt and loose paint. Ambient temperature 10-30 degrees. The surface temperature must be at least 3 degrees above the dew point at the time of application. Concrete strength at least 35. The concrete is at least 28 days old (after full ashtray)

- Concrete floor – polishing a planetary diamond in a vacuum, or a blast or scrubbing whip.

- Steel floor – SAND cleaning SA-2.5 or ST-3 steel brushes

- Thorough cleaning dust, fat with lipid solvents such as M degreaser, dirt and loose paint.

- Primer 450 for damp floor or Epoxyden Floor Primer standard for dry floor.

- Filling large holes and sockets with epoxy grout.

- Opening infestation stitches and cracks and elastomeric filling with 225A.

- Casting threshold slot with diamond disc (mechanical anchor) 1 cm wide and 5 mm deep, in a steel connection with concrete – this slot will be 1 cm away from the steel.

Basic paint:

- The paint itself can be used as a foundation with quartz spread – but the penetration of concrete is lower than that of Epoxyden floor primer.

- Epoxyden Floor Primer/Epoxyden Floor Primer Universal or Primer 450 for damp floors.

Packaging:

- Variety shades: 3.4+1.6 = 5 liters. 10+5 = 15 liters

- Transparent: 3.4+1.7 = 5.1 kg, 10+5 = 15 kg

Storage:

- In a cool, shady place at room temperature.

- Keep lids tightly closed.

Epoxyden floor antislip

Epoxy Floor 100% Multi-Thickness Rough Anti-Slip

Shelf life:

- 24 months in the original packaging.

clearing tools:

- Thinner 4/100-D at the end of painting.

Safety:

- Not edible, keep out of reach of children.

- Be sure to vent properly while applying. If necessary, air must be provided.

- Wear goggles, durable gloves, protective clothing.

- In case of injury – rinse with plenty of soap and water and immediately seek medical attention.

- Be sure to carefully read the safety instructions on the label.

Warning:

- Do not mix with materials that have not been recommended by us.

- Avoid contact with the skin and eyes, causing dryness and irritation of the skin.

Quality review:

- In our factory laboratories according to the specifications

- ISO 9001-2015

Notes that the user:

This technical specification is for general non-binding information only. The product is a professional product for professionals only who have already acquired previous experience in its implementation. This specification does not serve as a substitute for counseling/guidance by an authorized consultant/instructor. It is mandatory to apply first to a small area for match testing before applying large areas. The content of this specification changes over time and updates are inserted, and updated versions must be requested. Names of professional consultants/instructors can be obtained by telephone. Read product MSDS safety instructions before starting work with it.

Manufactured by Denber Paints & Coatings Israel Ltd., PO. 690 Sderot, 80100, certified by the Standards Institute in accordance with ISO 9001-2015 standard.

Epoxyden floor antislip

Epoxy Floor 100% Multi-Thickness Rough Anti-Slip

Chemical resistance table:

| Ethanol 50% (Ethyl Alcohol) | APPROVED |

| Turpentine | APPROVED |

| Hot water 96 degrees for 12 hours | APPROVED |

| Saline acid 3% | APPROVED |

| Acetic acid 10% | APPROVED |

| Caustic soda 10% | APPROVED |

| Nitric Acid 10% | APPROVED |

| Formaldehyde 10% | APPROVED |

| 10% phosphoric acid (phosphorus) | APPROVED |

| Sulfuric acid 5% – sulfur (batteries) without tonal changes | APPROVED |

| Sodium chloride 10% | APPROVED |

| Glycerin | APPROVED |

| Iso propanol (which alcohol profile IPA) | APPROVED |

Epoxyden floor antislip

Epoxy Floor 100% Multi-Thickness Rough Anti-Slip

- For more information about Denber Paints and Denber Projects, please contact us by phone and/or to the company’s websites:

- company profile English also

- For more details please refer to the Denber website also

- For our Facebook page click here also

- To the Facebook page of the CEO of Denber also

- For more projects click here also

- To the article: Sealer for stone and concrete and marble also

- To the article: Thermal insulation in nanotechnology also

- article: Thermal insulation Thermosil 200 energy saving in green construction also

- Related article: Thermal insulation, floor coating also

- To the article: Thermal insulation in nanotechnology company Denber also

- Fire resistance of houses, hardwood and parquet floors, decks also

- Swelling paints for steel protection against fire – Fire retardant paint also

- Epoxy floor coating in casting and painting also

- Crystal epoxy resin for tables also

- To the article Sealing also

- The complete article on the sealing materials for roofs and walls also

- Sealing the floor of the balcony, terrace from rain also

- Mold, how to remove mold correctly and how to fight mold also

- “Sick” buildings – Antibacterial paints Bacterinoll/ Tutgum Bacterinol also

- Paint for aircraft Denbergloss Jets also

- Asphaltflex execution specification – Denber Paints also

- Denbergloss grainy car paint also

- Denbergloss Clear also

- Varnish for wood. How to choose the right varnish for wood also

- Crystal epoxy for tables from Denber also

- Paint for swimming pools, epoxy Epoxyden Dengal, performance specification also

- Color specification of quadrant helmets also

- For a free consultation, call Denber – Dr. Blen Evgenia – 050-3551549 / 050-3551551 also

- Need advice? Contact us by email: Denber@bezeqint.net or contact us at 08-9960794

English

English עברית

עברית Русский

Русский