Epoxyden Ship Abrasive Antislip

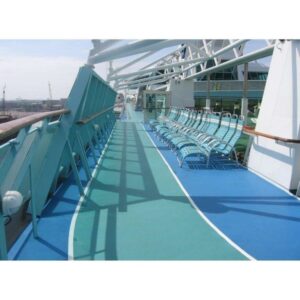

Fine/Medium Rough Anti-Slip Hard Coating for Vessels Deck and Step Areas – Rough Anti-Slip with Quartz

Anti-skid epoxy paint in a thin layer with fine/medium roughness.

Epoxyden Ship Abrasive Antislip. www.denber-paints.co.il

Ship antislip epoxy denber colors www.denber-paints.co.il

Rough anti-slip abrasive – mixed/transparent epoxy top paint, two-component, fine/medium rough decorative, for painting deck floors and anti-slip railings.

EPOXYDEN SHIP ABRASIV – TOP COAT TWO COMPONENT ABRSION RESIST FOR DECK FLOORS AND BANISTERS ANTI SLIP COATING IN SHIPS

Colored or transparent top paint with a fine/medium roughness (optional) for painting on Epoxy Ship Primer or on old epoxy castings for renewal and anti-slip coating, extra strong. Creates a strong rough decorative protective layer with high adhesion to epoxy primer for floors, railings, deck parts that tend to get wet and pose a slipping hazard.

Epoxyden Ship antislip www.denber-paints.co.il

Characteristics:

- Prevents slipping even when the floor is wet.

- Top paint for floors with mechanical strength and high adhesion to Epoxyd Ship Flour Primer.

- In many shades, creates a proper protection for the floor for durability in unusual conditions.

- Resistant to alkaline solutions and mixed acids and abnormal humidity conditions.

- powerful

- Easy to apply and repaint and dries quickly.

- Resistant to polluted industrial water.

- Resistant to fuels and oils including jet fuel

- and resistant to detergents.

- and resistant to scratches and blows.

- Suitable for painting industrial floors on which light equipment and carts move.

- Covers the floor with a thin and even decorative layer in shades with a subtle roughness.

- Excellent mechanical strength and resistance to wear under light loads.

- Resistant to momentary heat up to 200 degrees and more prolonged heat up to 150 degrees.

- Easy to repair at low cost.

- High coverage area.

- High electrical insulation.

Anti-skid epoxy paint in a thin layer with fine/medium roughness

uses:

- Epoxy for painting floors and stairs and railings in upper deck areas that are usually wet and present a slip hazard.

- As a top for walking floors inside the ship to prevent slipping while the ship is moving.

- For painting floors for pedestrians in galleries, shops, clubs, offices, sleeping compartments in trains and vessels, etc.

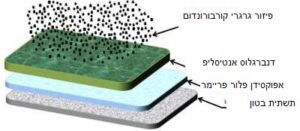

Technical data:

- Consumption per square meter – 1 liter per 4 square meters for a layer of 175 dry microns per layer.

- Flexibility – 1 mm (sheen) film 120 microns.

- Density – for matte gloss – 1.6-1.7 gm/cm 3 , (1475 (ASTM D

- Amount of solids – 65% Part A by weight 68%, Part B by volume 52% (ASTM-D-2369)

- Mixing ratio A:B – 2.5:1 by volume.

- Stiffness – >10 Dg (Ericsson)

- Abrasion – 120 microns – 3560 cycles (Gardner) ASTM

- Recommended layer thickness – 250 microns wet, 175 microns dry.

- Recommended number of layers – 1

- Pot life (working time from the moment of mixing A with B) – 4 hours.

Containing:

- Polyamide epoxy resin.

- Melanes, quartz, pigments.

- Polyamide keys.

- Solvents.

- additives.

Color:

- Transparent and any color from the RAL catalog.

Gloss:

- Glossy, silky, matte

- Matt. 10-30% (ASTM D 523)

This technical specification is for non-binding general information only.

Manufactured by Denber Paints and Coatings Israel Ltd. , PO Box 690 Sderot, 80100, certified by the Israeli Standards Institute in accordance with the ISO 9001-2015 standard.

For the full specification: anti-slip epoxy epoxy-ship abrasive also

Epoxy and polyurethane floor is done by the experts of Denber also

Recommendations: Magrek – the color of ships

Anti-skid epoxy paint in a thin layer with fine/medium roughness.

- For more information about Denber Paints and Denber Projects, please contact us by phone and/or to the company’s websites:

- company profile English also

- For more details please refer to the Denber website also

- For our Facebook page click here also

- To the Facebook page of the CEO of Denber also

- For more projects click here also

- To the article: Sealer for stone and concrete and marble also

- To the article: Thermal insulation in nanotechnology also

- Related article: Thermal insulation Thermosil 200 energy saving in green construction also

- Related article: Thermal insulation, floor coating also

- To the article: Thermal insulation in nanotechnology company Denber also

- For a free consultation, call Denber VP Dr. Blen Evgenia – 050-3551549 / 050-3551551 also

- To the article Sealing also

- Epoxy floor coating in casting and painting also

- The complete article on the sealing materials for roofs and walls also

- Asphaltflex execution specification – Denber Paints also

- Denbergloss grainy car paint also

- Lampert Denbergloss Clear also

- Crystal epoxy for tables from Denber also

- Paint for swimming pools, epoxy Epoxyden Dengal, performance specification also

- Color specification of quadrant helmets also

- Need advice? Contact us by email: Denber@bezeqint.net or contact us at 08-9960794 also

English

English עברית

עברית Русский

Русский