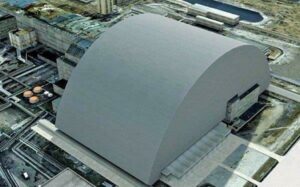

Entirad top radioactive radiation epoxy

Nuclear reactor repels radioactive radiation, easy to wash and neutralize, 100% multi-thickness solids.

Top coating for general painting in nuclear reactors

Epoxy antirad to radioactive radiation. Top coating for general painting in nuclear reactors. Special impenetrable epoxy, easily washed and neutralized without polluting residues.

Antirad top radioactive radiation epoxy. www.denber-paints.co.il

Gloss:

- High silk.

Touch drying :

- 4-6 hours, final for walking – 24 hours, final difficulty – 3 days.

Drying between layers:

- 6-24 hours depending on the ambient temperature. Fingerprint check.

Application methods:

- Brushing, rolling, pouring (on leveled horizontal surfaces), spraying (possible but less recommended).

Dilution:

- without dilution.

- To spray – dilutes 6/100. For large piston airless – can be given without dilution or 5-10%

Area preparation:

- Thorough cleaning of dust, grease, dirt and loose paint.

Packing:

- 3.4+1.6= 5 liters, 10+5 = 15 liters,

Top coating for general painting in nuclear reactors

Storage:

- In a cool and shady place at room temperature.

- Make sure lids are tightly closed.

Shelf Life:

- 12 months in the original packaging. and

Cleaning tools:

- Thinner XL after spraying. also

Safety:

- Not for food, keep out of reach of children. also

- Flammable, away from heat and fire. also

- Ensure adequate ventilation during application. also

- Wear safety glasses, solvent-resistant gloves, protective clothing. also

- In case of injury – seek medical attention immediately. also

Warning:

- Do not mix with materials not recommended by us. also

- Avoiding contact with the skin and eyes, causes dryness and irritation of the skin. In case of contact, wash with plenty of running water and seek medical attention. also

Quality Inspection:

- In the laboratories of our factory according to the specification. also

- ISO 9001-2015

For the attention of the user:

This technical specification is for non-binding general information only. The product is a professional product for professionals only who have already acquired previous experience in its application. Nothing written in this specification is used as a substitute for advice/training by a consultant/authorized guide . It must first be applied to a small area to check suitability before applying to large areas. The content of this specification changes over time and updates are introduced, current versions must be requested. Names of professional consultants/instructors You can get by phone. You must read the product’s MSDS safety instructions before starting to work with it.

Manufactured by Denber Paints and Coatings Israel Ltd. , PO Box 690 Sderot, 80100, certified by the Israeli Standards Institute in accordance with the ISO 9001-2015 standard.

Inspection at the Ministry of Defense UV resistance inspection at the Ministry of Defense

Top coating for general painting in nuclear reactors

- For more information about Denber Paints and Denber Projects, please contact us by phone and/or to the company’s websites:

- company profile English also

- For more details please refer to the Denber website also

- For our Facebook page click here also

- To the Facebook page of the CEO of Denber also

- For more projects click here also

- To the article: Sealer for stone and concrete and marble also

- To the article: Thermal insulation in nanotechnology also

- Related article: Thermal insulation Thermosil 200 energy saving in green construction also

- Related article: Thermal insulation, floor coating also

- To the article: Thermal insulation in nanotechnology company Denber also

- For a free consultation, call Denber VP Dr. Blen Evgenia – 050-3551549 / 050-3551551 also

- To the article Sealing also

- Epoxy floor coating in casting and painting also

- The complete article on the sealing materials for roofs and walls also

- Asphaltflex execution specification – Denber Paints also

- Denbergloss grainy car paint also

- Lampert Denbergloss Clear also

- Crystal epoxy for tables from Denber also

- Paint for swimming pools, epoxy Epoxyden Dengal, performance specification also

- Color specification of quadrant helmets also

- Need advice? Contact us by email: Denber@bezeqint.net or contact us at 08-9960794 also

English

English עברית

עברית Русский

Русский