MIL-P-53030A epoxy aqua primer

Aviation water-based epoxy primer, water-based epoxy primer, anti-rust, two-component, enriched with zinc phosphate manufactured according to MIL-P-53030A

White base epoxy paint for iron, anti-rust, water-based, anticorrosive without thinner.

Epoxydane aqua anticorrosive primer white zinc phosphate military/aviation.

MIL-P-53030A Epoxy Aqua Primer www.denber-paints.co.il

MIL-P-53030A Epoxy Aqua Primer www.denber-paints.co.il

EPOXYDEN AQUA WHITE PRIMER ZINC PHOSPHATE water base primer paint for iron steel, prevents corrosion

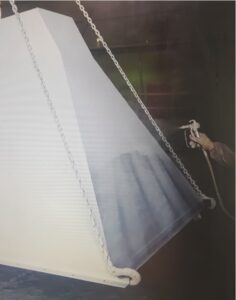

An especially strong epoxy primer for steel, enriched with zinc phosphate to prevent the development of rust. As a preparation before painting the top layer with polyurethane “Denbergloss”, epoxy or acrylic paints. Before coating/painting steel surfaces and corrugated tin such as stairs, walls, ceilings, partitions, steel floors, etc.

Epoxydane aqua anticorrosive primer white zinc phosphate military/aviation

Characteristics:

- A high-quality anticorrosive element prevents the development of rust.

- Very strong and adheres well to ferrous metals.

- Used as an ideal base color before painting with an upper decorative layer.

- Does not contain any thinners or volatile solvents.

- Does not harm the environment – does not emit thinner vapors.

- Water-based, easy to apply, odorless.

- Moisture barrier.

- Very washable and resistant to scrubbing.

- Enriched with zinc phosphate and prevents rust for a long time.

uses:

- Anticorrosive foundation for steel surfaces and corrugated tin.

- Painting walls, ceilings, partitions, hoods, humid rooms, bathrooms, etc.

- For painting in places where the use of thinners is prohibited, either for reasons of fire risk or maintaining air quality.

Technical data:

- Coverage capacity – 1 liter per 5-10 square meters

- 1 mm flexibility (Sheen)

- Density – 1.1-1.3 gm/cm 3

- Viscosity – 1000-3000 s (Brookfield)

- Stiffness – 3 Dg (Ericsson)

- Abrasion – 120 microns – 940 cycles (Gardner) ASTM

- Resistance to scrubbing – minimum 200 cycles according to the Israeli standard 1945

- Base to hardness ratio – 3:1 by volume

- Recommended layer thickness – 50-70 microns dry, (about 100 microns wet per layer)

- Recommended number of layers – 1-2

Epoxydane aqua anticorrosive primer white zinc phosphate military/aviation

containing:

- Fine epoxy resin.

- Melanins, pigments.

- zinc phosphate.

- Advanced plasticizers.

- Advanced fungicides, preservatives.

- Wetting and leveling agents.

- Taxotropic and other additives.

variety:

- white.

Lightning:

- Matte/silk/.

Touch drying :

- 1-2 hours.

Drying between layers:

- 4 hours. Final: 12-24 hours.

Application methods:

- Brushing, rolling, spraying. (Thesis in fistula or airless)

Dilution:

- water.

- First layer – 20-30%

- Second layer – 0-20%

MIL-P-53030A epoxy aqua primer

Epoxydane aqua anticorrosive primer white zinc phosphate military/aviation

Area preparation:

- Thorough cleaning of dust, grease, dirt and loose paint.

- Rust removal by sandblasting to grade SA-3 or steel brushes to grade ST-3

primary color:

- The color is a basic color.

packing:

- 3.75+1.25 = 5 liters, 13.5+4.5 = 18 liters.

This technical specification is for non-binding general information only.

Manufactured by Denber Paints and Coatings Israel Ltd. , PO Box 690 Sderot, 80100, certified by the Israeli Standards Institute in accordance with the ISO 9001-2015 standard.

For full specifications: MIL-P-53030A Epoxy Aqua Primer

Epoxydane aqua anticorrosive primer white zinc phosphate military/aviation

- For more information about Denber Paints and Denber Projects, please contact us by phone and/or to the company’s websites:

- company profile English also

- For more details please refer to the Denber website also

- For our Facebook page click here also

- To the Facebook page of the CEO of Denber also

- For more projects click here also

- To the article: Sealer for stone and concrete and marble also

- To the article: Thermal insulation in nanotechnology also

- Related article: Thermal insulation Thermosil 200 energy saving in green construction also

- Related article: Thermal insulation, floor coating also

- To the article: Thermal insulation in nanotechnology company Denber also

- For a free consultation, call Denber VP Dr. Blen Evgenia – 050-3551549 / 050-3551551 also

- To the article Sealing also

- Epoxy floor coating in casting and painting also

- The complete article on the sealing materials for roofs and walls also

- Asphaltflex execution specification – Denber Paints also

- Denbergloss grainy car paint also

- Lampert Denbergloss Clear also

- Crystal epoxy for tables from Denber also

- Paint for swimming pools, epoxy Epoxyden Dengal, performance specification also

- Color specification of quadrant helmets also

- Need advice? Contact us by email: Denber@bezeqint.net or contact us at 08-9960794 also

English

English עברית

עברית Русский

Русский