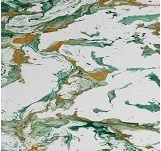

Liquid artificial marble

Artificial marble kitchen renovation and epoxy floor

Epoxy for renewing kitchen marble surfaces by casting and casting floors.

Liquid artificial marble.www.denber-paints.co.il

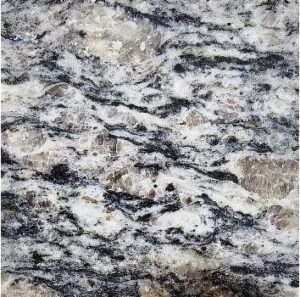

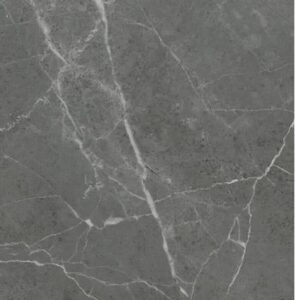

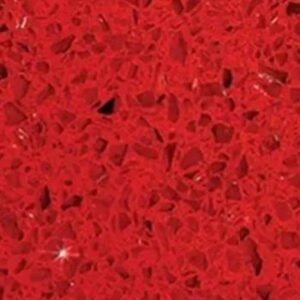

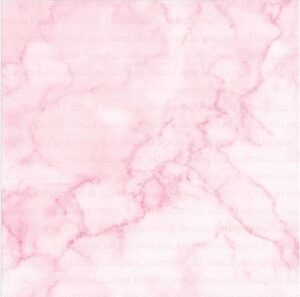

Thick high-performance epoxy in a variety of shades for the production of new artificial marble surfaces on wood, concrete, flooring or existing old marble. In a uniform shade with colored or shimmering fillers, or in background shades with veins or spots in shades for a natural marble-like texture. Unlimited selection of final results. Can be ordered in one shade and in a variety of other shades for wet-on-wet casting. You can add grains of black stone for a sparkling look, glitters for scattering, or a second transparent layer for a transparent glass look on top.

ARTIFICIAL MARBLE WITH EPOXY FOR THE KITCHEN AND FLOORS.

Uses:

- Casting decorative marble surfaces in the kitchen.

- Marble-like flooring.

Technical data:

- Coverage – 1 liter per 1 square meter in a layer of 1 mm.

- Recommended layer thickness – 1-3 mm and no limit.

- Base to hardener ratio – 2:1 by volume.

- Pot life = working time from the moment of mixing B+A to packing 5 liters – 20-30 minutes.

Color:

• transparent, all RAL shades,

Gloss:

• Shiny.

Epoxy for renewing kitchen marble surfaces by casting and casting floors

Renovation of marble surfaces – polishing and vacuuming. Cleaning with a cloth dipped in 6/100 thinner. Applying a primer layer: transparent epoxy fluor primer, mixing ratio 1:1 by volume. Fencing the area to be poured with a cant at the height of the thickness of the marble you want to pour, check with a level that everything is straight and balanced. Preparation of a 2:1 ratio epoxy mixture by volume in a desired background color – white for example. Pouring into the mold up to a height of 1 mm from the edge of the edge. Making a small amount again 2:1 ratio in another shade of black, for example, pouring thin stripes like hairs in marble. Waiting for drying. When still wet, you can add glitter powder, glass or mirror chips, black glittering corborundum grains, etc. After 24 hours, remove burrs, if the burr does not come out smooth, sand with 100 grit followed by “Zero” paper for polishing. You can apply Dunbargloss Clear varnish On the edge and on the surface, you can add a layer of transparent epoxy on the marble surface that will look like a glass surface coating.

Floor – polishing and vacuuming, cleaning with a cloth dipped in thinner 6/100. Applying a primer layer: transparent epoxy fluor primer, mixing ratio 1:1 by volume. Fencing the area for casting with adhesive paper in the doorways. Preparation of a 2:1 ratio epoxy mixture in a desired background shade – white for example. Casting and leveling with a toothed ruler to the desired thickness, (recommended about 3 mm), spreading wet on wet another color, for example black, and removing air with a spiked roller. You can go on the surface with spiked sandals and with gel to make shapes and veins that will look natural. You can add 1 mm transparent layer on top to get depth and a sort of glass coating that is spectacular in its beauty.

Packing:

- 3.4+1.6 = 5 liters. 10+5 = 15 liters

This technical specification is for non-binding general information only. and

manufactured by Denver Paints and Coatings Israel Ltd. , and

For the full specification: artificial marble kitchen renovation and floor with epoxy

Polishing and leveling. framing and casting. Removing the masking tape. Kant treatment. outcome

English

English עברית

עברית Русский

Русский