Epoxy putty flexible multi-thickness for building

Multi-thick two-component epoxy putty, flexible or hard to choose from

Suitable for creating rollers and slopes for floors and walls in industry in a corrosive atmosphere. Resistant to harsh and unusual conditions of chemicals and moisture as well as abrasion and vibrations, odorless and solvent-free. Suitable for repairs of all types of walls, including metal and wood, suitable for repairs of sewers and pipes, including oil.

EPOXY EPOXDEN CONSTRUCTION SCHPACHTEL/MORTAR ELASTIC Ointment epoxy for filling and fixing cracks and grooves in walls.

Epoxy putty flexible multi-thickness for building www.denber-paints.co.il

Characteristics:

- Very thick and powerful. Can be applied in one very thick layer with no thickness limit.

- Easy to work, easy to apply with a trowel. Dries quickly.

- 100% solids – does not contain water or thinners.

- Resistant to acids and alkalis, fresh and salt water as well as those mixed with industrial waste for a long time.

- Resistant to fuels and oils.

- and resistant to detergents and harsh chemicals. according to the attached table.

- High resistance to pressures and heavy loads. Resistant to blows and scratches.

- Suitable for the production of regular and designed rollers in the field before casting floors with epoxy or polyurethane.

- Excellent adhesion to epoxy, concrete, iron and wood layers.

- Suitable as putty for sealing and sealing as well as for leveling and smoothing broken concrete areas.

- Flexible and does not crumble in shocks.

uses:

- to restore concrete. for fracture repairs in concrete. For leveling and smoothing broken and crumbling concrete walls. to align and strengthen.

- As a putty for filling cracks and holes and depressions in concrete walls and floors before painting and/or coating.

- To create rollers in the floors before coating.

- To repair cracked/broken concrete pipes.

- For gluing steel spikes in construction additions.

- For anchoring steel rods and screws.

- For filling holes and gaps in prefab concrete and others. as well as for filling expansion joints with concrete.

- For anchoring machines in industry to the floor and repairing cracks in the floor.

- For concrete repairs in water and chemical pools, fiberglass containers, steel and others.

- For sealing cracks and gaps in all kinds of vessels.

- For anchoring vibrational bodies.

- For creating slopes in concrete floors for drainage, for flexible anchoring of stainless steel channels in food factories and industrial kitchens.

- For sealing water, petroleum, oil, fuel and chemical leaks in leaking pipes.

Multi-thick two-component epoxy putty, flexible or hard to choose from

Technical data:

- Average consumption – 3 liters per 1 square meter for a 3 mm thick layer.

- Density -0.2+ 9 gm/cm 3 .

- Viscosity – 20,000 cps (Brookfield).

- Stiffness – 10 < Dg (Ericsson).

- Flexibility – film 3 mm thick – 4 mm rod bending (SHEEN)

- Mixing ratio – 2:1 by volume (it is recommended to completely mix part A with part B to prevent mistakes in the mixing ratio).

- Elongation – 50%

- Abrasion – 120 microns – 5500 cycles (Gardner) ASTM.

- Recommended layer thickness – at least 3 mm and no thickness limit.

- Recommended number of layers – one thick layer.

- Working time with the mixture (pot life) – 20-30 minutes at an ambient temperature of 10-30 degrees.

- Tensile strength – 25MPa >

- Shear strength – 20> MPa

- and pull off tearing strength – 12MPa >

- Bending resistance – 16 MPa

- Compressive strength – 85 MPa / 800 kg per square meter

- Impact strength – 2.0 Dg/mm 2

- Adhesion to concrete – more than the strength of the concrete

variety:

- Gray, concrete gray. and

Lightning:

- Matt. and

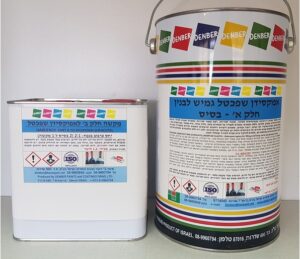

Packaging A + B :

- 1+0.5=1.5 liters, 3.4+1.6=5 liters, 12+6=18 liters and

For full specifications: epoxy putty, flexible, multi-thickness for building

English

English עברית

עברית Русский

Русский