Denber Paints & Coatings Israel

Denber paints and coatings Israel www.denber.net

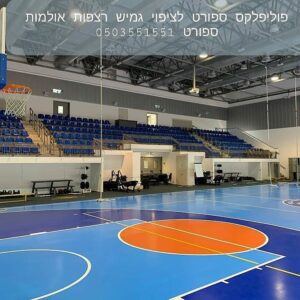

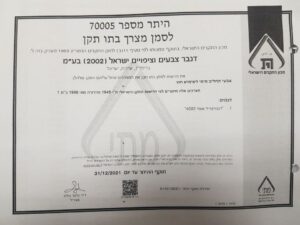

The Denber Paints and Coatings Israel factory is more than a place where paints are produced, it is a lifetime enterprise. It was established over 20 years ago by Dr. Belen Evgenia and Kogan Baruch. Both have a cumulative experience of over 30 years in the field. Since its establishment until today, the factory strives to bring its customers a comprehensive answer in the field of paints and coatings, and all this in the challenging reality of the city Sderot, which has been suffering from missile attacks for many years. Looking for paint or coating? There is no doubt that this is the factory to turn to.

English

English עברית

עברית Русский

Русский