Painting power station chimneys

Painting power station chimneys

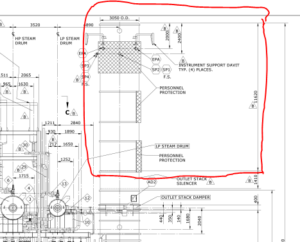

Specifications for painting gas power plant chimneys

This specification describes the preparation of the area and the colors required for marking chimneys according to the standard for air defense instructions. The standard comes to accurately describe what is required to prevent aircraft accidents.

Surface preparation: sand cleaning to grade SA-2 SSPC-SP6

Base color: zinc silicate 50-100 microns dry. (heat resistant 540 degrees)

Top color: white silicone beam 25-50 micron dry. (heat resistant 540 degrees)

According to the air defense instruction standard – IS5139 – the upper five meters of the chimney will be colored in three Equal stripes in colors: orange, white, orange. The thickness of the dry coating is 75-130 microns.

Estimated consumption for an example chimney: painting areas of the entire chimney, – 11,000 square meters.

1. First layer – zinc silicate base zinc 11 base + 25 zinc (50-100 dry mic) – about 1,300 liters – 72 sets.

2. Second layer – white silicone beam (25-50 microns dry) – about 1,100 liters – 61 18 liter cans

3. Chimney header 2 orange stripes 1 white between them. Area 471 square meters – 314 square meters 2 orange silicone beam strips – 35 liters – 2 18 liter bins.

Details of colors and marking instructions

Chimney gas power plant www.denber.net

2 orange stripes in the upper 5 meters of the chimney. Faded paint must be renewed every 1-3 years. and

Painting of power plant chimneys. Details of colors and marking instructions www.denber.net

Manufactured by Denber Paints and Coatings Israel Ltd

See also antenna towers acrylic paint and

English

English עברית

עברית Русский

Русский