Specifications for sealing roofs with Polyflex 2 (Denberseal 2)

Specifications for sealing roofs with Polyflex 2

Denberseal 2 is a two-component membrane for coating roofs that is durable for at least 10 years

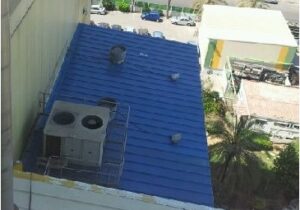

A system is required to perform a sealing coating for all types of roofs, resistant to standing water and erosion and UV resistant for a lot of pedestrian traffic such as service technicians and others on the roof with portable tools and small freight carts. The coating will be carried out after proper treatment of cracks and expansion seams in concrete roofs and treatment of rust in iscorium or insulated panel roofs and appropriate treatment for roofs covered with bituminous sheets. And the coating will be smooth and repels dust and dirt, the coating will be resistant to standing water indefinitely. The appropriate coating is a multi-thick UV-resistant monolithic polyurethane coating, on a suitable primer layer with a thickness of at least 1 mm for abrasion resistance for at least ten years . The casting layer will be performed in one casting of the entire layer or in two layers if the slope of the roof does not allow a thick casting.

Denberseal 2 is a two-component membrane for coating roofs that is durable for at least 10 years

Area preparation:

- If there is light grease on an existing coating and the grease has not penetrated the concrete – dissolve with degreaser Z by rubbing (road sweeper or machine) and washing with water and waiting for complete drying.

- If there is fat penetration into the concrete – spread an emulsifier into the N oil “for absorbing the fat” and wash with water until foam stops coming out and wait for complete drying.

- And if there is a layer of grease/hardened soot – spread carbon cleaner and rub until fully dissolved/softening and mechanical scraping until you get concrete free of oil/hardened soot, spread into N oil and rinse with water. Waiting for complete drying.

- For concrete/iscurite/panel/bitumen roofs – after removing grease if any, washing with high water pressure at least 150 atm.

- In concrete roofs – sealing holes and cracks and expansion joints with polyplex 225A certified with Cabosil.

- In Iskurit roofs/insulated panel – seal all screws and tin connections with polyplex 225A certified with Cabosil or with professional polyurethane mastics 600 grams. Each protruding screw must be wrapped and any space between the iscourit bins must be filled.

- And on roofs with bituminous sheets or tar – remove layers of white lime by high pressure washing up to 200 atm until you get clean sheets or clean black tar, repair holes and tears and loose sheet joints. Tears in sheets should be protected with a polyester mesh well dipped in polyplex 225A to hermetically close the tear or crack.

Denberseal 2 is a two-component membrane for coating roofs that is durable for at least 10 years

Primer layer:

- For concrete roofs – epoxy flour primer, mix part A + part B well with an electric stirrer until a uniform solution is obtained. Applying a layer of epoxy flour primer 1 liter per 5 square meters of concrete. By spraying/spraying. On an existing layer of old polyplex coating there is no requirement for a primer and provided that there are no gaps in the coating that expose the concrete. Even then, primer can be applied only to the bare areas after high-quality polishing until a white and clean concrete is obtained .

- For insulated roofs/insulated panel – if there is rust, polish with a disc or steel brushes or sandpaper any existing rust until you get a white and clean tin, clean well you can by vacuuming or a damp cloth dipped in acetone, and immediately paint with a layer of epoxy antirust rust converter 1 liter to 5 m2, if there is rust in parts of the roof, it is recommended to paint the whole thing with this color to prevent the development of rust under the coating which will cause the coating to swell and rise. If there is no rust, you can paint with standard epoxy primer 19.

- And for tar roofs / bituminous sheets – painting with a layer of water-based epoxy primer aqua to prevent the softening of the tar from the thinners in epoxy primers.

Denberseal 2 is a two-component membrane for coating roofs that is durable for at least 10 years

- If there are “bald areas” in the floor/large holes. – Differences in height must be filled with polyurethane grout 225A certified by Cabosil. – To reset heights and sequence the flow of rainwater.

- Preparation of grout mixture: mix part A + part B and add quartz into the bucket while mixing. until you get a thick mixture like concrete.

- The mixture should be poured immediately into the bald spots/holes. – and level two and a half with mulch until you get full compression and leveling to “zero” height.

Denberseal 2 is a two-component membrane for coating roofs that is durable for at least 10 years

Polyflex casting 225 A 100% solids:

- The casting can be done 4-24 hours after applying the primer. It is recommended after 4 hours to check the stickiness of the primer… – and if it is dry enough to walk on, it is recommended to start casting. The optimal time point to start casting. – He is the moment when with a strong press there is no fingerprint left on the primer. Waiting more than 24 hours may cause the primer to become very hard. – and a surface tension such that it will reject the top coating layer.

- If more than 24 hours have passed. – Apply another layer of primer before starting the casting. – and again wait for initial drying for about 4 hours.

- If there are areas where the load of use is particularly high. – Protect the area with polyester mesh. Spread polyester nets over the entire desired area in reverse layout to the direction of the roll. So that the nets lie without bumps on the surface with a 10 cm gap between them. Attach the nets to the primer with polyurethane mastic in several places so that they are completely stretched.

- Mix Polyplex Fluor 225A part A 15 liters + part B 5 liters and together 20 liters.

- Transfer to a clean container and mix again – mandatory. All this within up to 10 minutes to prevent heating and spoilage of the material.

- Immediately pour the entire mixture in the corner of the surface to be coated and level and evenly spread the material with a suitable roller or brushes or by any method convenient for the user. Add pouring sections until the entire roof coating is complete.

- Be sure to work quickly and intensively without breaks to maintain the casting sequence until the end.

- 24 hours drying

Denberseal 2 is a two-component membrane for coating roofs that is durable for at least 10 years

UV protection layer:

- A layer of 100% durable white acrylic Denbergloss polyurethane as a final protective top layer with a thickness of 120 microns wet

- Durability of at least 10 years.

- For roofs of surface parking lots see special specifications with this system suitable for driving vehicles.

Produced by Denber Paints and Coatings Israel Ltd

See also Denberseal® Roof Sealant Standing Water Resistant Sealant 1

See also the complete article on the sealing materials for roofs and walls

English

English עברית

עברית Русский

Русский