Paint for swimming pools, epoxy Epoxyden Dengal, performance specification

Paint for swimming pools, epoxy Epoxyden Dengal, performance specification

Paint for swimming pools, epoxy epoxyden dengle, performance specification

Swimming pools specification for painting with epoxy dengal

Introduction: Swimming pools as known today began to be built in the middle of the last century. These are used for fun swimming, sports, games and recreation. Among them are private pools in private homes, hotels and country clubs, urban public, competitive and sports pools. Some are covered and heated.

Paint for swimming pools epoxy epoxidan Dangal www.denber-paints.co.il

Swimming pools specification for painting with epoxy dangle

The pools are private – in the courtyards of the houses, they are mostly small and built of fiberglass, aluminum, concrete, industrial and Intex. Some are fixed in the ground in a hole dug in the garden and others are elevated with climbing steps.

The public pools – in kibbutzim, hotels, country clubs, municipal pools are large pools and are mostly made of concrete and/or aluminum. And besides smaller children’s pools and even a jacuzzi. These are rectangular and shaped and include waterfalls and slides. Some even have wave machines.

Training pools, competitive, Olympic, jacuzzi and endless – the training pools are small and designed for swimming against the current, the large competitive pools are 25 or 50 meters long, the Olympic pools are 50 meters long and 25 meters wide, divided into temperature-controlled lanes. The jacuzzi is a small heated pool with jets of water and air for massage. Such infinity pools that create the illusion that the water flows endlessly and connects with the horizon.

All pools are fitted with filtration and disinfection systems to protect the water from contamination.

The concrete, fiberglass, industrial, aluminum and intex pools are covered with mosaic, ceramic, pvc, vinyl or paint. These stand under water with chlorine and disinfectants and tend to wear out and must be renewed to look and restore its beauty. Some of the pools also sink and create cracks and breaks in the body of the pool and damage to the piping. Scale and deposits from the chlorine accumulate on the walls of the pools and the bottom, and together with oils from the sun protection creams create an ugly white coating.

Swimming pools specification for painting with epoxy dengle

Specifications for repairing and renewing coatings for swimming pools:

Area preparation: this part is of utmost importance for the success of the coating.

All types of pools must be thoroughly polished before starting treatment to remove any scale or contamination until a clean and stable infrastructure is reached. In Intex pools, work carefully so as not to damage the thin wall of the pool. At the end of the polishing, clean and vacuum the dust and clean the entire area with a cloth dipped and wrung out in D-4/100 thinner . In all types of pools with the exception of concrete or mosaic-coated pools, you can also wash with water and dry, then clean with thinner.

In concrete or mosaic and ceramic coated pools, work on a dry surface without wetting the surface. Water absorbed by the concrete or fumes may not dry until painting and cause damage by not allowing the paint to adhere well and then peel off relatively quickly.

The polishing also creates scratches to which the paint adheres better than without these scratches. Mosaic and ceramics should be polished until the glaze is removed and you get a well scratched surface without shine.

Treatment of cracks and fissures:

After we have thoroughly polished all the areas of the pool, we will take care of cracks in concrete or fiberglass and fumes if the pool is coated with mosaic or ceramic.

Concrete – widening the crack with a V profile diamond disk, cleaning and vacuuming, applying polyplex primer with a 1″ brush to coat the inside of the crack’s sides. Drying 30 minutes. Applying polyplex putty 225 to fill the crack.

Ceramics – opening pores with a V profile diamond disc, cleaning and vacuuming, applying polyplex primer with a 1″ brush to coat the face of the crack sides. Drying 30 minutes. Applying polyplex putty 225 to fill the crack.

Fiberglass – cleaning the crack and fine polishing. Filling with epoxy putty . Gluing a polyester mesh patch and covering the mesh with epoxy putty at least 3 mm thick. Waiting for drying. Adding a layer of Polyplex 225 flexible putty at least 1 mm thick and 10 cm around the patch (patch).

Swimming pools specification for painting with epoxy dangle

Thorough cleaning and painting:

A light finishing touch on putty repairs that have been made. Thorough cleaning without water. Cleaning with a cloth/cloth A clean towel dipped in 4/100 thinner and wrung out well. Rub the cloth with the thinner all the painted areas strongly so that the cloth is clean without any signs of dirt.

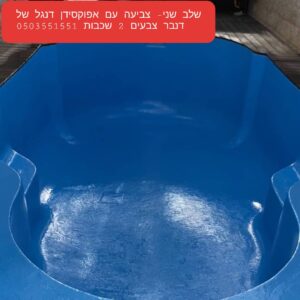

Open the container of light blue epoxy dangle paint . Mix the color. Pour the desired amount into a container and add hardener in a ratio of 2.5:1. (2.5 color + 1 difficulty). Mix well and add 5-10% of thinner 4/100 (it is not necessary to dilute with roller/brush painting) mix well and spray or paint with a roller/brush first layer the entire pool. First walls and later floor. Half a day or a full day later paint exactly like that again a second layer.

Intex and PVC pool exactly the same instructions with the exception of putty repairs which are only done in concrete, ceramic and fiberglass.

Swimming pools specification for painting with epoxy dangle

Aluminum pool: unlike all types of pools, for an aluminum pool, after thorough polishing and cleaning with a thinner, a yellow epoxy wash primer should also be applied, followed by 2 layers of light blue epoxy dangle .

At the end of the painting, routes can be marked with black or dark blue dangle epoxy, and the shallow/deep water border with red dangle epoxy.

3 days after drying, a second layer of epoxy dangle can be filled with water in the pool.

Denver Projects Company – Execution with over 30 years of experience

English

English עברית

עברית Русский

Русский