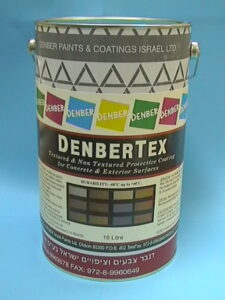

Denbertex Super White flate wall coat

Wall flexible solvent base paint

Non-textured protective high build coating, exterior flexible solvent walls coat. Flexible, smooth, thick, solvating coating is especially for exterior walls for ocean and extreme environmental endurance that lasts for many years. Durable and applicable at extreme temperatures. Seals out salts and conceals over minute cracks. Has a 13 year warranty. Decorative and smooth coat. Durable for morw than 25 years on exterior walls.

Denbertex Super White flate wall coat. www.denber-paints.co.il

Properties:

- Seals perfectly and prevents rain and moisture penetration.

- Breathes and allows moister vapors to evaporate from the inside outside.

- Endures UV rays.

- The polymer has 70 year lasting erosion endurance.

- Flexible and conceals over minute cracks.

- Applicable at low temperatures from -20°C.

- Durable in extreme conditions at temperatures from -60°C up to +60°C.

- Durable in acid rain and amog.

- Washable and repels dust and dirt.

- Smooth and decorative, white.

- Doesn’t rot, mold and fungus do not grow on it.

Denbertex Super White flate wall coat

Wall flexible solvent base paint

Applications:

- For exterior coating to seal buildings for many years.

- For exterior surface beautification.

- To solve erosion problems in salted areas.

- To renew old and cracked buildings.

- And To solve endurance problems where water based paints have failed.

- To spray on external rough walls for sealing and renewing.

Technical specifications:

- Theoretical coverage area: 10 square meters per liter.

- Actual required coverage area: 2-3 square meter per kg.

- Density: 1 .2-1.36 gm/cm3

- Flexibility: l mm (Sheen)

- Viscosity: 30,000 CPS (Brookfield)

- Hardness: > 3 Dg (Erichsen)

- Erosion: 1 20 microns 1 520 cycle (BYK Gardener) ASTM

- Recommended coat thickness: 1 mm (wet), 2 layers are recommended.

- Number of grams of water vapors passing per for 24 hours and 1 mm mercury pressure: 1.O

- Adhesion ability: 146 Newton per square centimeter.

Contains:

- Special acrylic styrene.

- Fillers, pigments.

- Flexibility substances.

- Solvents,additives.

Colors:

- White

Denbertex Super White flate wall coat

Wall flexible solvent base paint

Gloss:

- Matte silk ,

Touch-dry time:

- 30-60 minutes.

Drying time period between layers application:

- 8-24 hours.Final: 24 hours.

Application methods:

- Spraying- spray with an upper container for orange effect.

- Spraying with airless for flat coat.

- Brush, roller, spray.

Dilution:

- 0%-5% mineral turpentine or D-32

Surface preparations:

- Clean the surface from dirt.

Primer layer:

- Denbertex Primer is required.

- See technical specifications and surface preparations for this product.

Denbertex Super White flate wall coat

Wall flexible solvent base paint

Packaging:

- 18 liters.

Storage:

- In a shaded and cool place at room temperature with appropriate ventilation.

- Keep lid sealed.

Shelf life span:

- 12 months in its original package.

Equipment cleansing:

- Use mineral turpentine or D-32 thinner after use.

Quality control:

- In factory laboratories according to specifications.

- COA and COC certificate.

- ISO 9001-2015

Denbertex Super White flate wall coat

Safety precautions:

- Inedible, keep away from the reach of children.

- Flammable – keep distant from heated areas, fires, flames, and sparks, Prohibit smoking in working area.

- While applying, good air ventilation is important. In case there is not enough air, use ventilation according to the ventilation table.

- Wear protective glasses, gloves and suits.

- Avoid direct contact of the paint and/or thinner with the eyes and skin. In case of contact, immediately wash thoroughly with water.

- In case of an injury immediately get doctors assistance.

- Read the safety instructions on the labels.

- See M.S.D.S

Denbertex Super White flate wall coat

Wall flexible solvent base paint

- Visit our sites: www.denber-paints.co.il

- www.denber-colors.co.il

- Varnish for wood. How to choose the right varnish for wood

- Thermal isolation Thermoseal 200 energy saving in green construction

- Crystal epoxy resin for tables

- Fire resistance of houses, hardwood and parquet floors, decks

- Sealing the floor of the balcony, terrace from rain

- Thin floor nano-coverings for industrial refrigerators and freezers

- Epoxy floors – Benefits of epoxy floors

- Swelling paints for steel protection against fire – Fire retardant paint

- As part of the restoration of buildings – concrete restoration at the Yad Kennedy site

- Paint for aircraft Denbergloss Jets

- Complicated sealing based on innovative technologies

- Reconstruction project of a unique house (Israeli house of architect Gaudi); Renovation of condominiums

- The work on the floor covering and restoration of the sports hall has been completed

- Denber has developed an innovative solution for thermal insulation works

- Mold, how to remove mold correctly and how to fight mold

- “Sick” buildings – Antibacterial paints destroys viruses / bacteria – Bacterinoll/ Tutgum Bacterinol

- Denber – floor coating using epoxy and polyurethane – find out what is suitable for you epoxy floor or polyurethane floor

- Epoxy floor coating and epoxy paints

English

English עברית

עברית Русский

Русский