Thermoseal 200 nano thermal isolation paint

Acoustic and thermal isolation wall and roof paint

Thermoseal 200 nano thermal isolation www.denber-paints.co.il

acoustic and thermal isolation paint durable from -50oC up to 200oC

Thermal isolation – test no. 991321644 by the Israel institute of standards

Nano Ceramic flexible acrylic coat isolates noise, isolates heal and cold, seals and prevent condensation and mold. Isolating home/warehouses/industrial buildings walls/roofs, industrial pipes and furnaces, refrigeration and cooling facility ties. Durable in temp. -50oc and till +200°C

Thermoseal 200 nano thermal isolation paint

Professional white thin layer isolation material instead of thick rock wool that accumulate ate condensation humidity (that makes rust and rotten pipes), can be implementing by brush/spatula.

*Painting, sealing, isolating, all in one product

Thermoseal 200 nano thermal isolation paint

Acoustic and thermal isolation wall and roof paint

Characters:

- Thermal isolation creates constant energy economy

- Creates fine silent atmosphere in the rooms, enable stable climate control for better sleeping with no noises or temp. changes.

- Thin layer 1 mm equal to 5 cm . cotton wool/glass wool/rock wool.

- Can be sprayed for coating large spaces.

- Prevents condensation and mold.

- White color with excellent resistance to outdoor conditions, UV resistance, heat repellent.

- Reasonable mechanical strength. Excellent sealing characters.

- Breathing, allow vapor transition.

- Washable, easy to apply, fast drying, light weight, fire durable.

- Decrease sun temp. in metal roofs for min. 40% and decrease rain drops noise.

Applications:

- Heat exchangers and hot/cold pipes and taps, air conditioned channels in malls and etc.

- Tankers exterior walls and ceiling to reduce temp. and prevent evaporation and fire.

- Internal and external walls/roofs heal insulation and rain sealing and noise reduction.

- Isolating children rooms exterior walls from noise, heat and humidity.

- Musical/concerts/movie halls,

- Sleeping rooms in ships, trains.

- Motors housing,

- Hot pipes, tapes, stoves and chimney.

- Prevent escape of heat from stoves, pipes, kettles, reactors etc.

- Prevent escape of cold from refrigerator, pipes, etc.

- Suitable for tile roofs, bitumen, concrete, metal or any other sort,

Thermoseal 200 nano thermal isolation paint

Acoustic and thermal isolation wall and roof paint

Technical data:

- Theoretical surface coverage- l liter/0.66-1.0 m2

- Sun light reflection – 75%

- Solids – 80%

- Elongation – 30-65% (ASTM D-638)

- Max thickness; of one layer – 500 microns.

- Recommended layers number- 2-3 for home walls, for industrial use see table below.

- Flexibility- 1 mm (SHEEN).

- Viscosity- 7- 11 Pa.Sec (HAAKE).

- Density- 1.05-l.1 gr/cm3.

- Toughness- > 3 Dg (Erichsen).

- Abrasion- 1200 cycle (Gardener ASTM).

- Scrubbing – 350 cycles

- Salt spray – 3000 hr. (ASTM B- 117)

Recommended thickness layer for reducing pump temp. to 65 °c

| Liquid temp. in pipe | 110°C | 135°C | 175°C | 2150C | 235°C | 2500C | 260°C |

| Temp. on coat | 65°C | 65°C | 65°C | 65°C | 65°C | 65°C | 65°C |

| Thickness needed | 1.5

mm |

1.9 mm | 2.2 mm | 2.6 mm | 3.0 mm | 3.4 mm | 3.8

mm |

Thermoseal 200 nano thermal isolation paint

Acoustic and thermal isolation wall and roof paint

- Acoustics parameters:

- Thermoseal 200 coat of 3 mm on 10 cm gypsum isolated board provides acoustic isolation of Delta Lw=38db (ISO 140 chapter 8)

- Swallowing parameters NRC

| Thermoseal 200 dry film 1.0 mm | Thermoseal 200 dry film 2.0 mm | Thermoseal 200 dry film 3.0 mm |

| 0.45 | 0.55 | 0.60 |

- Blocking in db according the frequency for 3 mm coat on gypsum board

| Hz frequency | 65 | 125 | 250 | 500 | 1000 | 2000 | 4000 | 8000 |

| blocking in db STC-db | 16 | 18 | 22 | 27 | 30 | 33 | 38 | 42 |

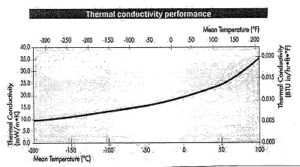

Thermal conductivity 20cm concrete + 1 mm thermoseal 200:

- -40OC – 0.015 W/m.k

- -20OC – 0.018 W/m.k

- 0OC – 0.020 W/m.k

- +10O – 0.021 W/m.k

- +30OC – 0.023 W/m.k

- +500OC – 0.025 W/m.k

Thermoseal 200 nano thermal isolation paint

Acoustic and thermal isolation wall and roof paint

Content:

- Special acrylic polyurethane emulsion.

- Flexibility improvers.

- Pigments, dryers, ceramic fillers, wetting materials.

- Fungicides, additives, UV resistance improvers.

- Thixotropic agents and others.

Tints: white

Gloss: matte

Touch-Dry:

- < 3 hours, depending on thickness and temp.

- Thin layers dry faster.

Dry time between layers:

- < 24 hours.

| Painted Surface temp. | 5- 1 2°C | 13-20°C | 21-30°C | |||||||||

| % humidity | 10-30 | 31-50 | 51 -70 | >70 | 10-30 | 31 -50 | 51-70 | >70 | 10-30 | 31 -50 | 51 -70 | >71 |

| Dry time between coats | 8-12

hr. |

10-16

hr. |

12-20

hr. |

20-24

hr. |

4-6

hr. |

5-8

hr. |

6-10

hr. |

10-12

hr. |

1-2

hr. |

2-3

hr. |

2.5-3.5

hr. |

3.5-4

hr. |

Thermoseal 200 nano thermal isolation paint

Acoustic and thermal isolation wall and roof paint

| Painted Surface temp. | 31 -400C | 41-50oC | 51-60°C | ||||||||||

| % humidity | 10-30 | 31 -50 | 51 -70 | >70 | 10-30 | 31 -51 | 151 -70 | >70 | 10-30 | 31 -50

|

51 -70 | >71 | |

| Dry time between coats | 1-1.3

hr. |

1.2-1.5

hr. |

1.5-1.8

hr. |

1.8-3

hr. |

0.5-0.7

hr. |

0.7-1

hr. |

0.8-1.2

hr. |

1 .2-2

hr. |

0.3-0.5

hr. |

0.4-0.8

hr. |

0.5-l

hr. |

1 -1.5

hr. |

|

Final drying time:

- <24 hr. in summer

- <3 days in winter

Implementing method:

- Brush, Spray, Roller.

Dilution:

- 20 – 30% with water for first layer.

- 5 – 20% with water for second layer.

- Can apply with no dilution by spatula.

Surface preparation:

- Must be clean from dust, dirt, unstable paint.

- External walls – water high pressure cleaning > 150 bar. fill holes with “Denberspachtel”

- Metal pipes/walls/roofs- clean the metal to “white metal” level by sand blasting or chemical cleaning with ” Degreezer 3000″ and flush with water.

- Paint on suitable primer

Thermoseal 200 nano thermal isolation paint

Acoustic and thermal isolation wall and roof paint

Primer Paint:

- Walls – painted or plastered and roofs concrete or tiles – Denbertex primer.

- Wooden walls/roofs – Denbertex primer.

- Plaster, concrete, asbestos- Denbertex Primer.

- Galvanized- Tutgum Galvanize.

- Hot pipes <120°C – Epoxyden primer

- Hot pipes > 120°C – Zinc silicate (till 600°C)

Packing:

- 5 and 18 liters.

Storage:

- Store in well shaded place, room temp. with appropriate ventilation.

- Keep lids tightly closed.

Shelf Life:

12 months in original package

Tools Cleaning:

- At the end of the application with D-18 Thinner or Mineral Turpentine.

Quality control:

- In factory laboratories according to specifications.

- COA and COC certificate.

- ISO 9001-2015

Thermoseal 200 nano thermal isolation paint

Acoustic and thermal isolation wall and roof paint

Safety precautions:

- Inedible, keep away from the reach of children.

- Wear protective glasses, gloves and suits.

- Avoid direct contact of the paint with the eyes and skin. In case of contact, immediately wash thoroughly with water.

- In case of an injury immediately get doctors assistance.

- Read the safety instructions on the labels.

- See M.S.D.S

C.O.C – Certificate Of Analysis

we certify that product : Thermoseal 200

Produced according: DEF 1110 Cat. No. 017174

Batch No. 011405 Packing unit: 18 lit.

Meets our specifications for this product with the following actual data:

| Covering ability (m2\kg) | 11.1 | > 10 |

| Viscosity (Pa-s) sec/Pols (Haake) | 10 | 7-11 |

| Binder grinding fineness (Micron) /Heg | 20 | < 25 |

| Elasticity (mm) bending (Sheen) | 1 | < 3 |

| Elongation | 50 | 30-65% |

| Hardness kg (N x 10) | 10 | > 5 |

| Touch dry time (hours) 250 mic. | 40 min. | < 1 hr. |

|

|

|

| Density (kg/Iit) | 1.05 | 1.0-1.1 |

| Gloss % 60° | 4 | < 6 |

| Pull off test | 275 | >200psi |

| Color (After 24 hour drying) | Off white | Fed. St. 955-no.37875/0ff white |

| Flash point | none | > 25 °C |

| Scratch resistance after 7 days (750 gr.) | O.K | The metal shall not be seen through the scratch |

| Package, label, marking | O.K | Acc. 3-21/lsrael standard 2302 |

| Storage stability – 10 days, 40 °c | O.K | No sagging or separation |

| Flexibility and adhesion after 13 days | O.K. | Shall not show cracking or loss of adhesion |

| Crisscross 1 mm adhesion test Israel std. 785 chapter 14 | O.K. | No loss of adhesion permitted |

|

|

20 cm concrete +1 mm Thermoseal 200

ASTM C-177 RVE TEST |

Humidity + UV Cabinet 3000 hr. In cycles

Acoustic and thermal isolation wall and roof paint |

O.K. no visual change | 8 hr. lamp 60° 4 hr. humidity in 50 °c |

| Accelerated wearing out humidity cabinet 40 °c | O.K. | 14 days |

| % solids | 80 | lsrael std. 785 chapter 17 |

| Visual stability 24 hour after applying | O.K | Smooth, free of sagging and wrinkling |

| Time of drying-up (hours). The two coats | 4 | < 4 |

|

|

|

| Resistance to distilled water-48 hr. dipping | O.K. | Shall not be softening |

| Resistance to mineral oil 50 °c for two hr. (after 4 day drying) | O.K. | No deterioration |

| Resistance to white spirit 40 °c for 1 hr. | O.K. | No softening |

| Salt spray 5% – 3000 hr. – 125 days (two coats) 33-36 °c (ASTM B-117) | O.K. | Slight sings of breakdown allowed |

Thermoseal 200 nano thermal isolation paint

Acoustic and thermal isolation wall and roof paint

- Visit our sites: www.denber-paints.co.il

- www.denber-colors.co.il

- Varnish for wood. How to choose the right varnish for wood

- Thermal isolation Thermoseal 200 energy saving in green construction

- Crystal epoxy resin for tables

- Fire resistance of houses, hardwood and parquet floors, decks

- Sealing the floor of the balcony, terrace from rain

- Thin floor nano-coverings for industrial refrigerators and freezers

- Epoxy floors – Benefits of epoxy floors

- Swelling paints for steel protection against fire – Fire retardant paint

- As part of the restoration of buildings – concrete restoration at the Yad Kennedy site

- Paint for aircraft Denbergloss Jets

- Complicated sealing based on innovative technologies

- Reconstruction project of a unique house (Israeli house of architect Gaudi); Renovation of condominiums

- The work on the floor covering and restoration of the sports hall has been completed

- Denber has developed an innovative solution for thermal insulation works

- Mold, how to remove mold correctly and how to fight mold

- “Sick” buildings – Antibacterial paints destroys viruses / bacteria – Bacterinoll/ Tutgum Bacterinol

- Denber – floor coating using epoxy and polyurethane – find out what is suitable for you epoxy floor or polyurethane floor

- Epoxy floor coating and epoxy paints

English

English עברית

עברית Русский

Русский