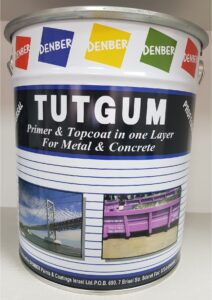

DTM Tutgum Universal – Direct To Metal

Direct to metal primer and topcoat in one paint

DTM Tutgum Universal. www.denber-paints.co.il

Primer and top coat for iron metal, aluminum and galvanized steel.

Single component primer and top coat paint that is based on unique solvent acrylic copolymers with phosphate zinc pigments that adhere outstandingly to black iron, aluminum and galvanized steel after surface preparations. The paint is strong durable, thick, anticorrosive and is used as a primer and a top coat all in one layer application creating a smooth and elegant finish.

Properties:

- Industrial and professional use only.

- Has a very strong adhering ability to iron, aluminum and galvanized steel.

- High build, applicable in one thick layer.

- Provides long lasting rust prevention.

- Used as a decorative final layer.

- Fast drying, can be repainted within an hour.

- Primer and a top coat all in one paint.

- Has an excellent connection between different layers.

- Durable in heat and extreme weather conditions.

- Suitable in salty and chemical conditions.

- A 400 micron layer is applicable for extreme demands.

- Hard, scratch durable and shock resistant.

DTM Tutgum Universal – Direct To Metal

Direct to metal primer and topcoat in one paint

Applications:

- For coating metal grates and railings, metal objects and parts.

- For painting light and electric columns.

- For aluminum products, galvanize products and iron products.

- For industrial equipment.

Technical specifications:

- Theoretical cover area; 15-20 sqm per liter.

- Cover area at the recommend layer width: 8 sqm per liter.

- Recommended layer thickness: 125 microns.

- Number of recommended layers; .1-2

- Flexibility: 1 mm (SHEEN)

- Density; 1.1 -1.4 gm/cm3

- Viscosity: 2-2.5 parsec (HAAKE)

- Rigidity; over 3 Dg (Ericsen)

Contains:

- Copolymer-acrylic resins.

- Special flexibility substances,

- Phosphate zinc and zinc magnesium oxide.

- UV ray endurance additives.

- Pigments, solvents and additives.

Colors:

- White and a various number of colors.

DTM Tutgum Universal – Direct To Metal

Direct to metal primer and topcoat in one paint

Gloss:

- Matte, silk, and shiny.

Touch-dry time:

- 20-40 minutes.(avoid over spraying)

- If dust is formed while spraying add a retarder .

Drying time period between layer application:

- 1-4 hours. Final: 2-6 hours.

Application methods:

- Brush. spray, roll.

Dilution:

- Brush/roll: 5% – 10% D-18 thinner or mineral turpentine.

- For slower drying and creating a surface without any brushing marks use the D-32 thinner.

- Spraying: 15% – 20% D-18 thinner 3-4 atm.

- Airless: ,5% 4-5 atm atm. nozzle 0.01 5″-0.018″..

DTM Tutgum Universal – Direct To Metal

Direct to metal primer and topcoat in one paint

Surface preparations:

- Black steel: Remove rust by sand cleaning (SA-2.5) or by mechanical or chemical cleansing (Dagrizer 3000) until receiving while steel. Remove grease thoroughly with Dagrizm·M. Aluminum: Remove grease with Dagrizer M. etch with Antrox ,14 yellow passivatoin with Pasivtor .1722

- Galvanizing: Lightly polish to remove zinc salt and completely remove the galvanized shine, polish with sandpaper or a disk, after removing the shine clean the surface with degreezer M to completely remove all grease.(Dont wipe the surface with the same rags, avoid spreading old grease on 0ther parts of the surface)

- Old galvanization: Harshly polish lo remove rust, lightly polish where zinc salt and shine should be rwoved, and remove b’fcasc with Degreezer M.

- * Strict supervision is required while preparing the surface according to the instructions, which is the costumer’s complete responsibility. If the instructions will not be completely fulfilled the paint will peel.

Packaging:

- 0.5 liter. 0.75 liter. 2.5 liter, 5 liters, 18 liters.

Storage:

- In a shaded and cool place at room temperature.

Shelf life span:

- 12 months in its original package.

Equipment cleansing:

- Use thinner D-1 8 or mineral turpentine.

DTM Tutgum Universal – Direct To Metal

Direct to metal primer and topcoat in one paint

Safety precautions:

- Not eatable, keep away from the reach of children.

- Flammable. keep distant from heated areas, fires, flames, and sparks Wear protective glasses, gloves and suits.

- Check that there is enough air while applying.

- In case of an injury immediately get doctors assistance.

Warnings:

Don’t mix with other substances that are not recomended by us.

Quality control:

- ISO 9001-2015

- In our factorys laboratories under these standards.

DTM Tutgum Universal – Direct To Metal

Direct to metal primer and topcoat in one paint

- Visit our sites: www.denber-paints.co.il

- www.denber-colors.co.il

- Varnish for wood. How to choose the right varnish for wood

- Thermal isolation Thermoseal 200 energy saving in green construction

- Crystal epoxy resin for tables

- Fire resistance of houses, hardwood and parquet floors, decks

- Sealing the floor of the balcony, terrace from rain

- Thin floor nano-coverings for industrial refrigerators and freezers

- Epoxy floors – Benefits of epoxy floors

- Swelling paints for steel protection against fire – Fire retardant paint

- As part of the restoration of buildings – concrete restoration at the Yad Kennedy site

- Paint for aircraft Denbergloss Jets

- Complicated sealing based on innovative technologies

- Reconstruction project of a unique house (Israeli house of architect Gaudi); Renovation of condominiums

- The work on the floor covering and restoration of the sports hall has been completed

- Denber has developed an innovative solution for thermal insulation works

- Mold, how to remove mold correctly and how to fight mold

- “Sick” buildings – Antibacterial paints destroys viruses / bacteria – Bacterinoll/ Tutgum Bacterinol

- Denber – floor coating using epoxy and polyurethane – find out what is suitable for you epoxy floor or polyurethane floor

- Epoxy floor coating and epoxy paints

DTM Tutgum Universal. www.denber-paints.co.il

English

English עברית

עברית Русский

Русский